Written by Shalen Sehgal | CEO

In today’s interconnected world, your supply chain’s resilience could be the difference between business continuity and costly disruptions. With supply chains stretching across the globe and encompassing various tiers of suppliers and partners, the ability to swiftly respond to disruptions is paramount. Businesses must integrate crisis management software and robust business continuity planning to navigate these complexities effectively.

This blog delves into how these tools and strategies can fortify your supply chain, highlighting how Crises Control can play a pivotal role in enhancing your resilience.

Understanding Supply Chain Resilience

Supply chain resilience refers to a company’s ability to anticipate, respond to, and recover from disruptions, ensuring that operations continue smoothly despite unforeseen challenges. In a landscape where supply chains are increasingly extended and intertwined with numerous third-party services—ranging from raw materials to outsourced IT support—the potential for disruptions grows.

To achieve true resilience, companies need more than just reactive strategies; they must build a proactive framework that incorporates both crisis management and continuity planning. This involves:

- Visibility: Gaining a comprehensive view of the entire supply chain, including direct and indirect suppliers, is crucial for identifying potential weak spots and ensuring smooth operations. With full visibility, you can track the flow of goods, monitor supplier performance, and quickly spot any disruptions or delays. This level of insight enables proactive management, allowing you to anticipate issues before they escalate into significant problems. By having a clear understanding of every link in your supply chain, you can make informed decisions that enhance overall resilience.

- Risk Assessment: Identifying and evaluating potential threats is essential for safeguarding your supply chain. This involves analysing the risks associated with each supplier, geographical location, and operational process, and understanding how these risks could impact your business. Whether it’s natural disasters, geopolitical tensions, or supplier insolvency, a thorough risk assessment helps prioritise which threats need the most attention. By understanding the potential impact of these risks, you can allocate resources effectively and implement measures to mitigate them, ensuring that your supply chain remains robust even under pressure.

- Response Planning: Developing strategies to manage and mitigate the effects of disruptions is the final step in building a resilient supply chain. This involves creating detailed response plans that outline the actions to be taken when a disruption occurs, including alternative sourcing strategies, communication protocols, and contingency plans. Clear response planning ensures that everyone involved knows their roles and responsibilities, and that there is a coordinated effort to address the issue. Effective response planning minimises downtime, preserves critical operations, and helps maintain customer trust, making it a cornerstone of supply chain resilience.

The Role of Business Continuity Planning in Enhancing Supply Chain Resilience

Business continuity planning (BCP) is the process of creating systems of prevention and recovery to deal with potential threats to a company. Effective BCP ensures that an organisation can maintain essential functions during and after a crisis.

Key Elements of Effective BCP for Supply Chains

- Risk Analysis and Impact Assessment: Understanding the potential impact of disruptions on your supply chain is crucial. This involves evaluating how different types of disruptions could affect operations and establishing the potential consequences for various scenarios.

- Supplier Assessment: Assessing the continuity plans of your suppliers is essential. Ensure that their BC plans are robust and align with your own standards. If a supplier’s plans are lacking, it could pose a risk to your operations.

- Recovery Strategies: Developing detailed recovery plans that include strategies for alternative suppliers, logistical adjustments, and communication protocols helps ensure that your supply chain can quickly adapt and recover from disruptions.

- Regular Testing and Updates: Regularly testing your BCP and updating it based on new risks and changing circumstances is vital to maintaining its effectiveness.

Leveraging Crisis Management Software for Supply Chain Resilience

Crisis management software plays a crucial role in managing and mitigating supply chain disruptions. These tools provide a structured approach to handling crises, ensuring that communication and coordination are streamlined.

Key Features of Crisis Management Software

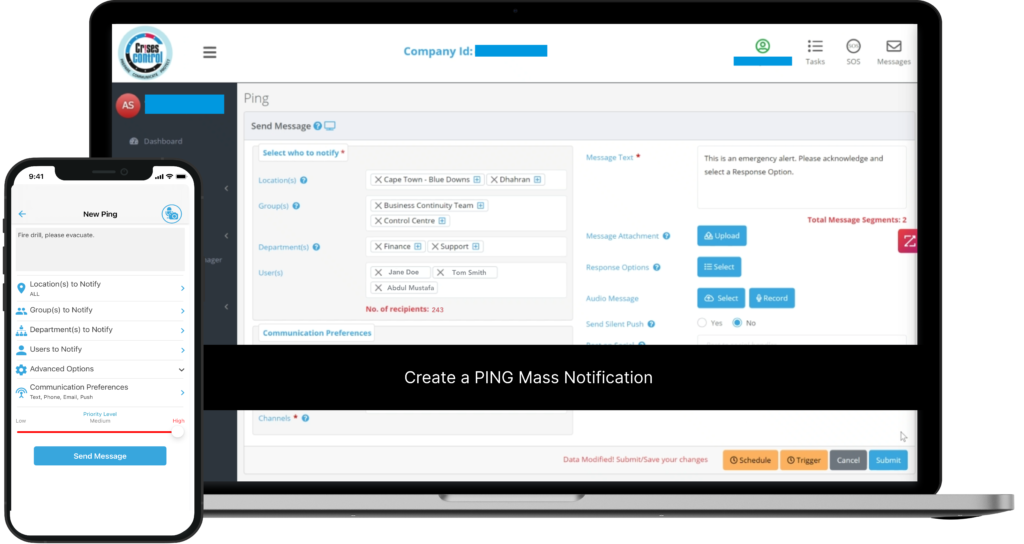

- Mass Notification Systems: Quickly disseminate critical information to all stakeholders involved in your supply chain. This feature is crucial for maintaining communication during disruptions and coordinating responses effectively.

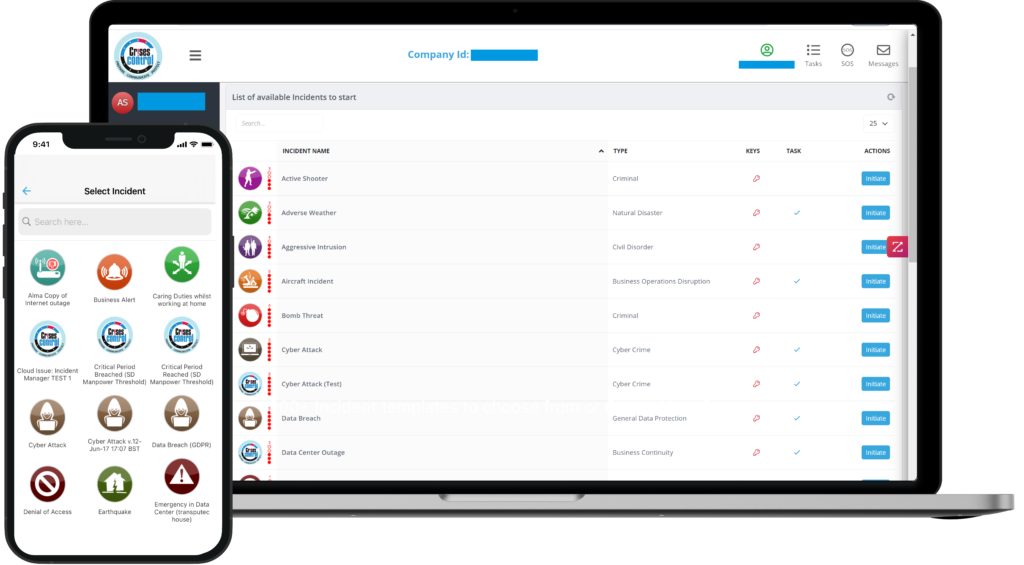

- Incident Management: Manage and track incidents in real-time, providing a comprehensive view of the situation and ensuring that all necessary actions are taken to address the crisis.

- Task Management and Incident Planning: Develop and assign tasks related to incident response and recovery. This ensures that all necessary steps are taken and responsibilities are clearly defined.

- Reporting and Auditing: Track and analyse incident responses to improve future crisis management strategies and maintain transparency.

How Crises Control Enhances Supply Chain Resilience

Crises Control offers a comprehensive suite of tools designed to enhance supply chain resilience through effective crisis management and business continuity planning.

Advanced Mass Notification

Crises Control’s Ping mass notification system ensures that you can quickly and effectively communicate with all relevant parties in your supply chain, regardless of the disruption’s scale. This helps minimise confusion and keeps everyone informed.

Interested in our Ping Mass Notification Software?

Efficiently alert everyone in seconds at scale with our Mass Notification System – PING, get the message out fast and ensure rapid response and recovery.

Integrated Incident Management

With Crises Control, you can manage and monitor incidents in real-time, providing you with the information needed to make informed decisions and coordinate a swift response.

Task Manager

This tool allows you to assign, track, and manage tasks related to incident response and recovery, ensuring that every action is accounted for and completed in a timely manner.

Incident Plan Builder

The Incident Plan Builder enables you to choose from 200+ predefined incident plans to create your own detailed incident response plans, clearly defining roles, responsibilities, and procedures to follow in case of a crisis.

SOS Panic Button

This feature provides a quick alert system for emergencies, allowing you to initiate an immediate response and protect your supply chain operations.

Easy Integration

Crises Control integrates seamlessly with your existing systems and suppliers, ensuring that you can maintain continuity without significant disruptions.

Comprehensive Reporting

Detailed reporting and audit capabilities help you review and improve your crisis management strategies, ensuring that your supply chain remains resilient in the face of future challenges.

Interested in our Incident Management Software?

Customise your Crisis Incident Management Software to meet your specific needs with our flexible tools & stay connected and informed during the crisis and incident management process

Conclusion

Building a resilient supply chain requires a proactive approach that integrates crisis management software and robust business continuity planning. By leveraging advanced tools and strategies, you can enhance your ability to respond to and recover from disruptions, ensuring that your operations remain uninterrupted.

To see how Crises Control can help you build a more resilient supply chain, contact us for a free personalised demo. Discover how our solutions can provide the visibility, coordination, and response capabilities you need to protect your business and ensure continuity.

Request a FREE Demo