Written by Anneri Fourie | Crises Control Executive

Factories and warehouses are among the most hazardous workplaces, where fires, chemical spills, and machinery failures can put employees at serious risk. When emergencies strike, every second counts. Slow response times, poor communication, and outdated safety protocols can lead to serious injuries, fatalities, and operational shutdowns.

Traditional safety measures, such as fire drills, manual reporting, and noticeboard instructions, are no longer enough to protect workers in high-risk environments. The reality is that emergencies are unpredictable, and businesses need a faster, more efficient way to manage workplace safety.

This is where Mass Notification Software plays a critical role. By providing real-time alerts, structured emergency response workflows, and automated incident management, it ensures that employees are protected at all times.

The Most Common Industrial Hazards: A Safety Time Bomb

Factories and warehouses are filled with risks that can quickly escalate into disasters. Identifying these hazards is the first step in creating a safer work environment.

1. Fire and Explosions: A Devastating Threat

Industrial fires can start from electrical faults, overheated machinery, flammable materials, or even a small human error. According to the National Fire Protection Association (NFPA), industrial and manufacturing properties account for over 37,000 fires annually, causing injuries, fatalities, and millions in damages.

The biggest challenges include:

- Delayed detection: Fires can spread rapidly, and without immediate alerts, employees may not have enough time to evacuate.

- Poor evacuation procedures: Workers often don’t know the fastest or safest route to escape.

- Ineffective communication: Emergency messages may not reach employees working in different areas of the facility.

2. Hazardous Chemical Spills: Invisible Dangers

Factories use and store hazardous chemicals daily. When spills occur, they can cause toxic exposure, fires, or explosions. Regulatory bodies like the Health and Safety Executive (HSE) impose strict penalties for poor chemical handling, yet many companies still struggle with outdated response procedures.

Key risks include:

- Health hazards: Chemical exposure can lead to respiratory issues, burns, or poisoning.

- Environmental damage: Spilled chemicals can contaminate water supplies and surrounding areas.

- Slow containment: Without an immediate response, spills can spread and become more difficult to control.

3. Machinery Failures: Silent Killers

Industrial machines are essential for operations, but they can also be dangerous. According to the National Safety Council, contact with objects and equipment is the third leading cause of work-related deaths and the second leading cause of nonfatal injuries involving days away from work. In 2022, there were 738 fatalities and 780,690 injuries reported in this category.

Common challenges include:

- Unnoticed malfunctions: Faults may not be detected until it’s too late.

- Inability to shut down quickly: Some machines keep running even when an emergency occurs.

- Slow emergency response: Injured workers may not receive medical help in time.

Why Traditional Safety Protocols Are No Longer Enough

Many factories and warehouses still rely on outdated safety measures, assuming that fire drills and safety posters are enough. However, in real emergencies, these methods often fail due to:

- Slow communication: Word-of-mouth and manual call trees delay response times.

- Lack of real-time alerts: Employees and emergency responders may not receive critical updates quickly enough.

- Confusion during incidents: Workers may not know what actions to take, leading to panic and mistakes.

- Inconsistent incident tracking: Paper-based records make it difficult to learn from past incidents and improve safety procedures.

This is why companies are adopting Mass Notification Software and Incident Management Software to improve emergency response times and protect their employees.

How Mass Notification Software Protects Workers

1. Instant Mass Notifications for Emergency Alerts

When a fire, chemical spill, or machinery failure occurs, a Mass Notification Software ensures that all employees receive real-time alerts. Messages can be sent through multiple channels, including SMS, email, push notifications, and voice calls. This guarantees that employees are informed immediately, no matter where they are in the facility.

2. Automated Emergency Response Plans

Instead of relying on employees to remember safety protocols, this software automates emergency workflows. Workers receive clear step-by-step instructions on their mobile devices, ensuring they know exactly what to do.

For example, if a fire breaks out, the system can:

- Alert all employees in the affected area.

- Provide evacuation routes based on their location.

- Notify emergency services promptly.

3. Real-Time Location Tracking and SOS Alerts

During an emergency, knowing the location of employees is critical. Mass Notification Software e for factories and warehouses includes GPS tracking, allowing emergency responders to find workers in distress. The SOS panic button feature enables employees to call for immediate help with a single tap of a button.

4. Incident Reporting and Compliance Audits

Tracking incidents helps businesses improve their safety measures. Incident Management Software allows companies to:

- Maintain digital incident logs.

- Generate compliance reports for regulatory bodies.

- Identify patterns to prevent future incidents.

How Crises Control Enhances Workplace Safety

Crises Control offers a comprehensive solution designed for high-risk industrial environments. Here’s how it protects factory and warehouse workers:

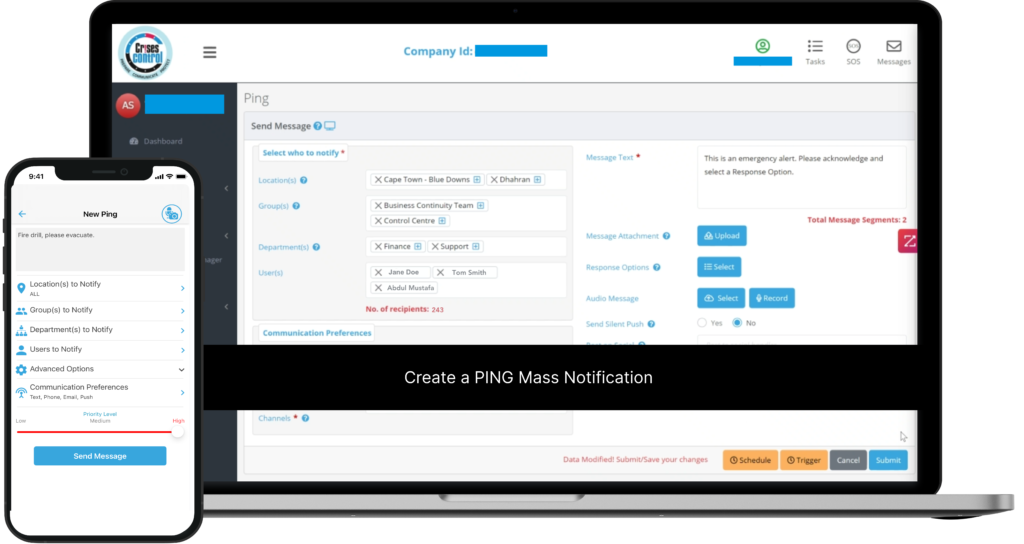

1. Ping Mass Notification System

- Sends emergency alerts instantly across multiple communication channels.

- Ensures messages reach employees in different locations and shifts.

2. Incident Management System

- Automates emergency workflows, reducing human error.

- Provides real-time updates to managers and first responders.

3. SOS Panic Button for Immediate Assistance

- Allows workers to request help with one tap.

- Shares precise location data for faster response.

4. Task Manager for Emergency Procedures

- Assigns and tracks critical safety tasks.

- Ensures that fire drills, chemical handling protocols, and equipment maintenance procedures are followed correctly.

5. Compliance and Audit Reporting

- Stores incident records securely for future audits.

- Helps businesses meet regulatory requirements and avoid fines.

Interested in our Ping Mass Notification Software?

Efficiently alert everyone in seconds at scale with our Mass Notification Software – PING, get the message out fast and ensure rapid response and recovery.

Conclusion: Take Control of Workplace Safety Before It’s Too Late

Factories and warehouses will always be high-risk environments, but preventable disasters should never be the reason employees get injured, or worse. Fires, chemical spills, and equipment failures can happen at any time, but with the right safety solutions in place, businesses can minimise risk, protect their workers, and keep operations running smoothly.

Crises Control provides real-time alerts, automated emergency response, and powerful incident management features, ensuring that your workforce is always protected.

Don’t wait for a disaster to strike, take proactive steps to improve workplace safety today.

Get a free personalised demo and see how Crises Control can enhance safety in your factory or warehouse.

Request a FREE Demo