Written by Anneri Fourie | Marketing Executive

In the world of manufacturing, maintaining operational continuity during a crisis is critical. Whether it’s a machinery breakdown, supply chain disruption, or a natural disaster, how well you handle these situations can determine whether you face a minor setback or a significant disruption. Effective crisis management strategies are essential to keep your operations running smoothly when unexpected challenges arise.

This blog will explore key strategies for manufacturing companies to stay operational during a crisis and highlight how Crises Control’s advanced solutions can support your business continuity efforts.

1. Identifying Key Risks and Crisis Scenarios

To effectively manage crises, you first need to understand the risks that could impact your manufacturing processes. Recognising potential threats allows you to prepare proactive measures and mitigate their impact.

Common Risks

- Equipment Failures: Equipment breakdowns can halt production and lead to costly delays. For example, a malfunctioning conveyor belt or a faulty robotic arm could stop an entire assembly line.

- Supply Chain Disruptions: Issues with suppliers or logistics can disrupt your production schedule. Imagine a key supplier of raw materials suddenly goes out of business or a shipping delay causes a shortage of crucial components.

- Natural Disasters: Events like earthquakes, floods, and fires can damage your facilities and infrastructure. For instance, a fire in your warehouse could destroy inventory and affect production.

- Cybersecurity Threats: Cyberattacks can compromise your data and disrupt operations. A ransomware attack might lock you out of critical systems or expose sensitive information.

How Crises Control Can Help

Crises Control’s Crisis Management Software offers comprehensive tools to anticipate and prepare for these risks. With real-time data and risk assessments, you can identify potential threats and develop tailored strategies to address them effectively. For instance, our software can help you conduct risk assessments and create contingency plans for each identified risk.

2. Developing a Comprehensive Business Continuity Plan

A well-developed business continuity plan (BCP) is crucial for ensuring that your manufacturing operations remain functional during and after a crisis. A BCP outlines procedures for maintaining essential functions, managing resources, and communicating with stakeholders.

Key Components

- Risk Assessment: Begin by evaluating potential impacts on your operations and prioritising critical functions. Identify which processes are essential for your business’s survival and focus on protecting them.

- Recovery Strategies: Develop clear procedures for quick recovery, including backup plans for equipment and resources. For example, setting up a secondary production site or maintaining backup inventory can help you resume operations quickly.

- Communication Protocols: Establish channels for internal and external communication to keep everyone informed. Create a communication plan that includes contact information for key stakeholders, such as suppliers, customers, and emergency services.

How Crises Control Can Help

Crises Control’s platform allows you to digitise your business continuity plan, storing it securely in the cloud for easy access. This ensures that your plan is always up-to-date and available to your team, regardless of the situation. You can access your plan from anywhere and update it as needed to reflect changes in your operations.

3. Implementing Effective Mass Notification Systems

During a crisis, timely and clear communication is crucial. Mass notification systems help ensure that all employees, suppliers, and stakeholders receive real-time updates and instructions.

Key Features

- Alerting Mechanisms: Use multiple channels such as SMS, email, and voice calls to reach everyone promptly. For instance, sending an SMS alert to all employees can quickly inform them of a sudden production halt.

- Real-Time Updates: Ensure that information is disseminated quickly to minimise confusion and facilitate swift action. An effective system should allow you to send updates in real-time and track their delivery status.

How Crises Control Can Help

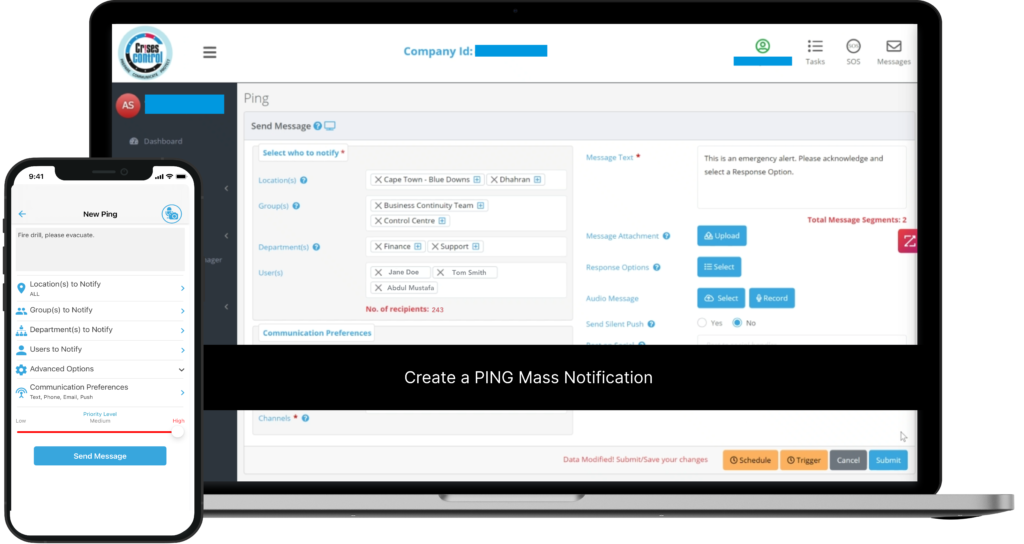

Crises Control’s Ping Mass Notification system provides seamless communication across various platforms. This ensures that everyone is informed and can respond effectively to the crisis. With our system, you can send alerts through multiple channels, track their delivery, and ensure that critical information reaches all intended recipients.

Interested in our Ping Mass Notification Software?

Efficiently alert everyone in seconds at scale with our Mass Notification System – PING, get the message out fast and ensure rapid response and recovery.

4. Automating Incident Response and Task Management

Effective crisis management requires a structured approach to incident response. Automating incident management and task assignments can streamline the process, ensuring that critical tasks are completed promptly and efficiently.

Key Practices

- Incident Tracking: Monitor the progress of response efforts in real-time. Use dashboards to track incident status, resource allocation, and response actions.

- Task Automation: Automatically assign tasks and set deadlines to ensure accountability and timely completion. For example, automatically assigning specific team members to handle equipment repairs or manage inventory can streamline your response efforts.

How Crises Control Can Help

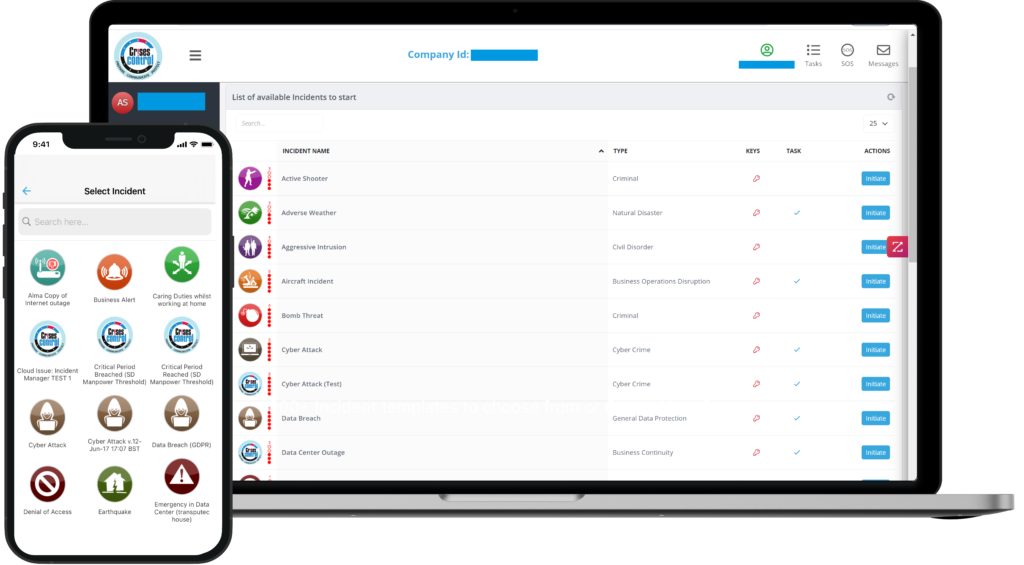

Crises Control’s Incident Manager and Task Manager features allow you to automate and track crisis response efforts. Our platform helps you assign tasks, monitor progress, and ensure that every action is completed efficiently. This reduces the risk of missed steps and improves overall response effectiveness.

Interested in our Incident Management Software?

Customise your Crisis Incident Management Software to meet your specific needs with our flexible tools & stay connected and informed during the crisis and incident management process

5. Conducting Regular Crisis Simulations and Training

Training and simulations are essential for preparing your team to handle real-life crises. Regularly testing your response plans helps identify weaknesses and ensures that your employees are familiar with their roles during an emergency.

Key Strategies

- Simulation Exercises: Conduct tabletop exercises and simulations to practise crisis scenarios. For example, simulate a supply chain disruption or equipment failure to test your team’s response.

- Training Programs: Provide ongoing training to keep your team informed and prepared. Regularly update training materials and conduct refresher courses to ensure that your employees are up-to-date with the latest procedures and technologies.

How Crises Control Can Help

Crises Control’s platform supports crisis simulations and training exercises. You can use our tools to test various scenarios, evaluate your team’s performance, and refine your response plans. Regular simulations help improve preparedness and ensure that your team is ready for any situation.

6. Ensuring Supply Chain Resilience

A resilient supply chain is crucial for maintaining operational continuity. Developing strategies to mitigate the impact of disruptions on your supply chain ensures that you can adapt quickly and minimise downtime.

Key Practices

- Supplier Management: Identify and establish relationships with alternative suppliers. Having backup suppliers in place can reduce the risk of delays and ensure that you have access to critical materials.

- Inventory Management: Maintain adequate inventory levels to buffer against supply chain interruptions. Regularly review and adjust inventory levels based on current demand and potential risks.

How Crises Control Can Help

Crises Control’s Incident Plan Builder helps you map out potential supply chain risks and prepare responses. You can create contingency plans for supply chain disruptions, identify alternative suppliers, and ensure that you can quickly adapt to changes in your supply chain.

Conclusion

Mastering crisis management strategies is essential for manufacturing companies to ensure operational resilience during emergencies. By developing comprehensive business continuity plans, implementing effective communication systems, automating incident response, and conducting regular training, you can safeguard your operations and minimise disruptions.

Crises Control offers the tools and solutions you need to enhance your crisis management efforts and maintain operational resilience. Our advanced crisis management software helps you navigate crises confidently, ensuring that your manufacturing processes remain on track.

Ready to elevate your crisis management strategies? Contact us today to get a free demo of Crises Control and see how our solutions can help your manufacturing company stay operational during any crisis.

Request a FREE Demo